Research and prototyping

The integration of new technologies applied to furniture and semi-manufactured products for wood is an important commitment that the firm has been sustaining for over ten years to anticipate the constant evolution of the customers’ needs.

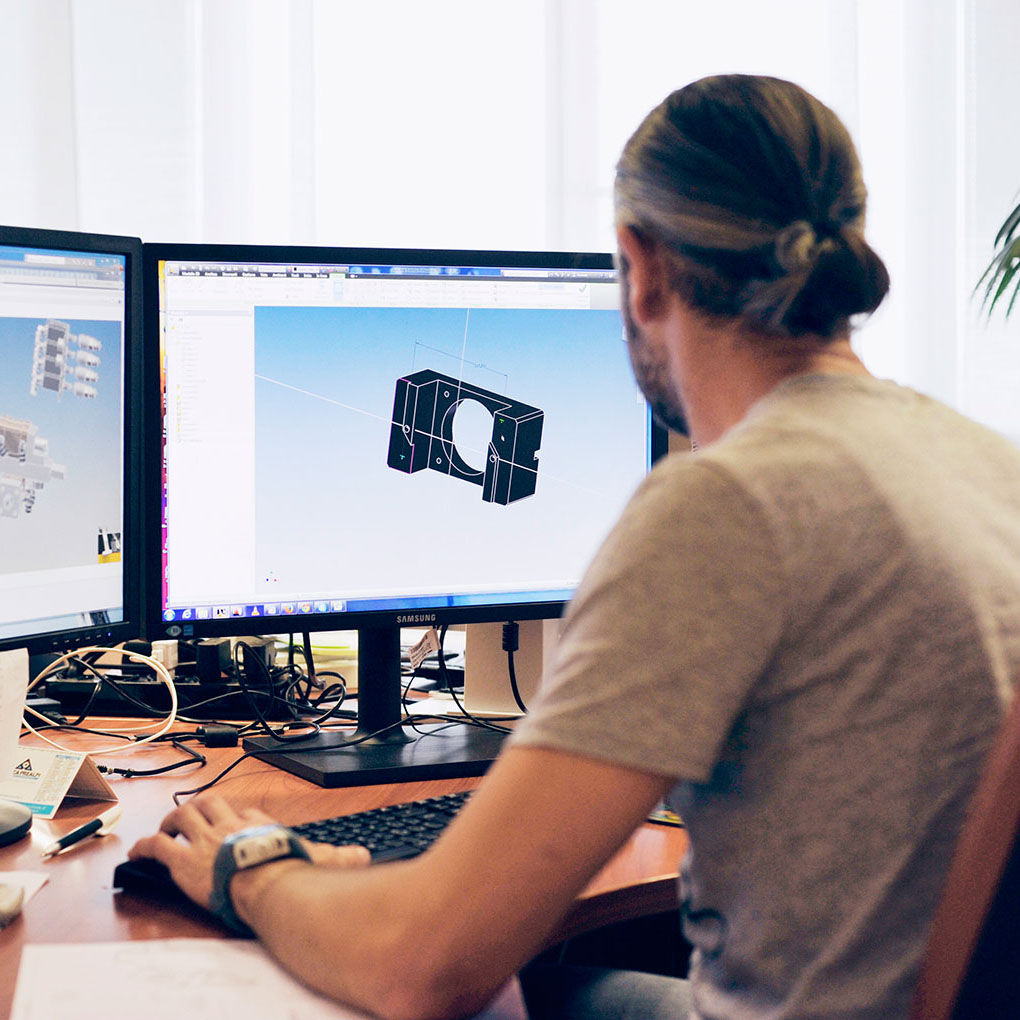

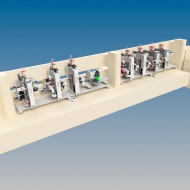

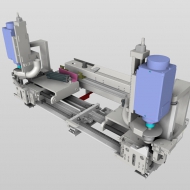

We choose to invest in an internal design office to study and prototype groups, automations and complete machines. The prototypes are then realized with our machining centers and our 3D printer by our specialist staff.

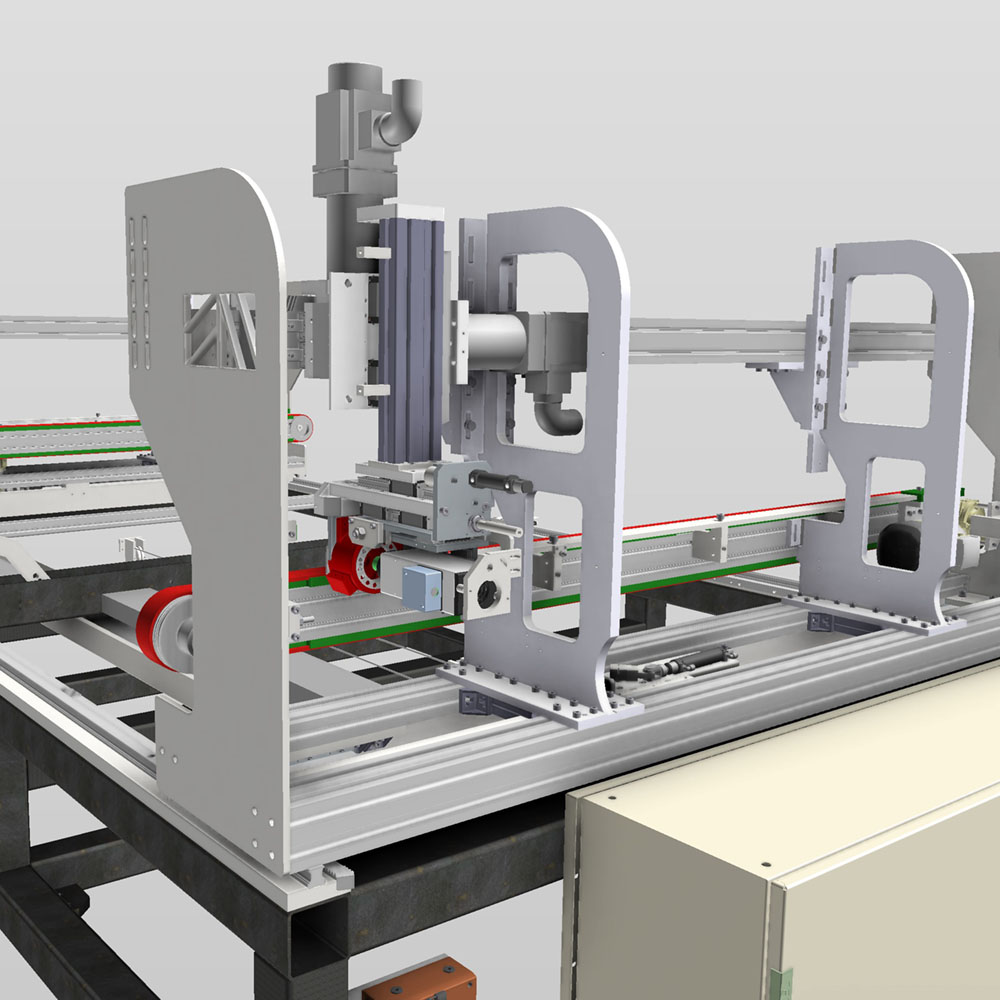

We internally design and build wood working machines and their dedicated components, which are exclusive and customized.

We make custom-made projects for customer in need of maximum privacy where the entire process is carried out exclusively. Zanin Nello has always reserved its customers’ interests.

Innovation and Development

Determination and constancy are two key elements in the development of new projects. Zanin Nell is characterized for the technology push of its ideas, which permits to find efficient solutions to new demands in an increasingly variable market.

We can supply a “turn-key” service from the prototyping research to small-series production and we are able to satisfy the most demanding customer.

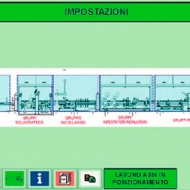

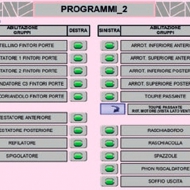

Zanin Nello software

We develop software for the management and the use of wood working machinery. The software can be installed on groups or new machinery of our production. Furthermore, our software can be used on serviced machinery or modified with the implementation/substitution of components (retrofitting).

Our software is customizable on customer request. It is easy to use and it allows standardizing the rolling stocks, with more efficiency and productivity of the machinery.